AI-powered Maintenance

Transforming maintenance strategy in the steel industry

Challenge

Reducing costs and failures in manufacturing production is crucial for improving efficiency and profitability. However, several challenges must be addressed to achieve these goals. Key challenges include optimizing processes, managing complex supply chains, maintaining product quality and reducing defects, implementing effective equipment maintenance strategies, addressing the workforce skill gap, integrating automation and new technologies and balancing market demand with production schedules.

Overcoming these challenges requires a comprehensive approach that involves leveraging data and analytics, embracing technology, investing in workforce development, and fostering a proactive mindset. By tackling these challenges, manufacturers can achieve cost reductions, minimize failures, and enhance overall production efficiency.

RINA solution

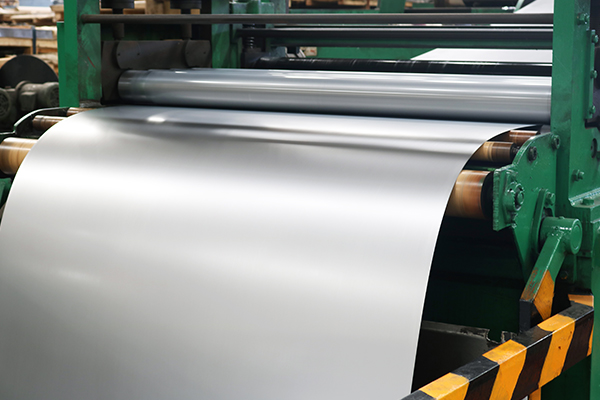

Capitalizing the extensive RINA knowledge on steel manufacturing processes, and expertise in data analysis and modelling, streaming analytics tools and predictive maintenance models were implemented for production chain and machine control to allow early detection of deviations and failure in production route and machines so avoiding production losses.

Such AI-based models were then integrated in an industry-tailored Big Data application framework as solution to online decision support tasks in manufacturing sector (mechanic and pharmaceutical). This architectural integration allowed to efficiently process large volumes of structured and unstructured data (such as pictures, videos, and sensor data) within a short processing time, therefore being able to successfully combine high-dimensional data analysis with complex event processing and accommodating the unique characteristics of manufacturing processes and production routes for a wide range of machineries in different plant settings.

These advanced technologies in conjunction with real-time monitoring of process key performance indicators, enabled the detection of component anomalies before a breakdown occurred allowing to maintain product quality and therefore avoiding defect costs that impact 5% to 30% of total revenue.

Benefit for the stakeholders

RINA empowered a digital transformation strategy from scheduled maintenance to predictive maintenance where efforts can lead to cost reductions of 10% to 30%, bringing benefit not only on the client but also on the client’s customers. This transformation was possible by establishing a robust data collection infrastructure with a strong orientation to data awareness through by bespoken interfaces for real-time machine status monitoring.

This capability allows production managers for estimating the residual useful life of machine parts effectively reducing downtime caused by unexpected failures which is crucial as equipment failures not only incurred repair costs but also led to production losses (around $50 billion annually in the United States).

Demonstrating the potential of AI for transforming maintenance in steel manufacturing, RINA solutions enable a series of key benefits such as:

- Reduction in Unplanned Downtimes: through the implementation of early warning systems, the solution successfully minimized unplanned downtimes. By leveraging predictive maintenance techniques, potential failures are detected in advance, allowing for timely interventions and preventing unexpected disruptions to the production process.

- Decreased Roll Consumption: through the implementation of optimized maintenance practices, the solution successfully reduced roll consumption. By accurately assessing the condition of rolls and implementing proactive maintenance measures, the lifespan of rolls is extended, resulting in significant cost savings.

- Improved Lifetime of Bearings and Drive Trains: the focus on maintenance optimization resulted in improved recommended lifetimes for bearings and drive trains. By leveraging advanced analytics and predictive maintenance models, the usage of these components is optimized, leading to enhanced durability and prolonged operational life.

- Optimal Equipment Utilization: the solution emphasized the optimal utilization of existing equipment, eliminating the need for additional investments. By implementing efficient maintenance practices and leveraging AI-driven analytics, the performance and longevity of machinery and rolls is maximized, ensuring their optimal utilization throughout their lifecycle.